Excel today... expand tomorrow!

The Opal XII, part of the Modular High Speed Production Machines, belongs to the

top-of-the-line Assembléon’ SMD pick & place machines.

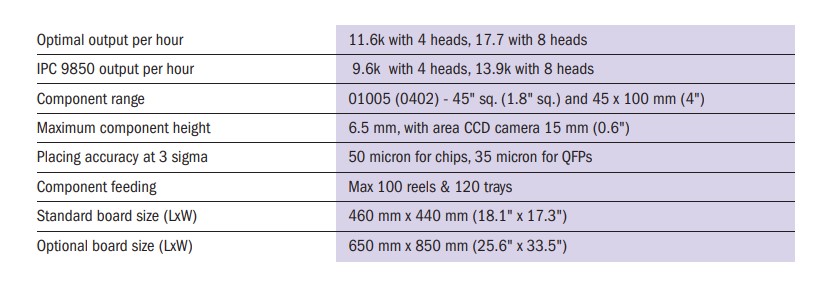

■ 9.6k / 11.6k cph (IPC 9850 / rated for Opal-X” with 4 heads)

■ 13.9k / 17.7k cph (IPC 9850 / rated for Opal-X” with 8 heads)

■ 01005 (0402) – 45 mm sq. (1.8” sq.) Fine Pitch

■ Accuracy: 35 microns @ 3 sigma

■ 100 mm (4”) long connectors

■ Centralized network database

■ Max 100 reels & 120 trays

■ On-machine inventory tracking

■ Remote diagnostics

The Opal-XII is a High Speed flexible machine that can handle a wide range of

components at speeds up to 12,500 SMDs per hour. The machine is built around a very

rigid, vibration-free frame for improved accuracy and long-term stability and is perfectly

suitable for round-the-clock production.

The Opal-XII features a high precision single placement beam carrying 4 Super Fine heads

with exchangeable nozzles. The placement beam moves in X/Y and Z direction, while the

board and component feeders are stationary. A flexible board transport system enables

the Opal-XII to handle virtually any type of PCB, with or without tooling pins. Board

conveyor width is automatically adjustable, allowing board dimensions up to 460 x

440mm (17.9″ x 17.2″) to be handled.

The newly designed vision system with Line Array camera allows fast and accurate “onthe-fly” alignment of a wide range of components from 0201 up to 45mm square PLCC,

including 45mm square QFPs with lead pitches down to 0.5mm (20 mil). Dark

background BGAs, µBGAs and CSPs with ball pitches down to 0.5mm (20 mil) and ball

diameters down to 0.3mm (12 mil) can be recognized with the use of new developed

illumination unit which allows measurement of ball positions and dimensions.

An optional single area CCD camera extends the component range to 32mm square ICs

with lead pitches down to 0.4mm (16 mil). The vision system detects missing, bent or

irregular spaced leads or BGA balls; faulty components are rejected.

A separate camera system monitors fiducial marks at the board, circuit and component

level, using a combination of white-light and IR LEDs with multi-angle diffusers to

provide optimal illumination.

Just six nozzle shapes are required to cover the specified SMD range. High output levels

are therefore achieved, as the need for nozzle exchanges is minimal. An optional 20

position nozzle exchange station enables additional special nozzles to be

accommodated.

Up to 100 tape feeders can be loaded on the Opal-XII. The machine supports tape, stick,

bulk and tray feeders.

The tape feeder design for the Opal-XII allows simultaneous picking from any mix of tape

feeders ranging from 8 to 56mm.

A Windows NT based controller, running an user-friendly Graphical User Interface, allows

the Opal-XII to be used stand-alone or in-line. The controller includes a Management

Information System (MIS) that continuously gathers production data for management

feedback. The unique bad mark sensing capabilities allow a multi-circuit panel to be run

as one large board, thus maximizing placement speed while still using bad mark

information. A laser-based verification system, which guarantees correct feeder latching,

is standard.

The Opal-XII is fully compatible with the other-XII serie machines which use the same

feeders, feederbars, software and controller. Off-line feeder changeover can be achieved

by using a 20 position Feederbar Exchange System (FES). An entire feederbar can be

conveniently loaded off-line, minimizing change-over time.

A basic program optimization function is also included in the machine as standard

which can be used during production. For more advanced machine optimization and/or

line balancing, the new Production Preparation System allows you to create and

optimize SMD machine programs on a PC instead of using the SMD machine.

The Opal-XII is basically a scaled-down version of the Topaz-XII with slightly lower component output but with the same placement accuracy and board size. Both systems place everything from 01005 components to large CSPs, Flip Chips, BGAs and fi ne pitch QFPs.